Product Description

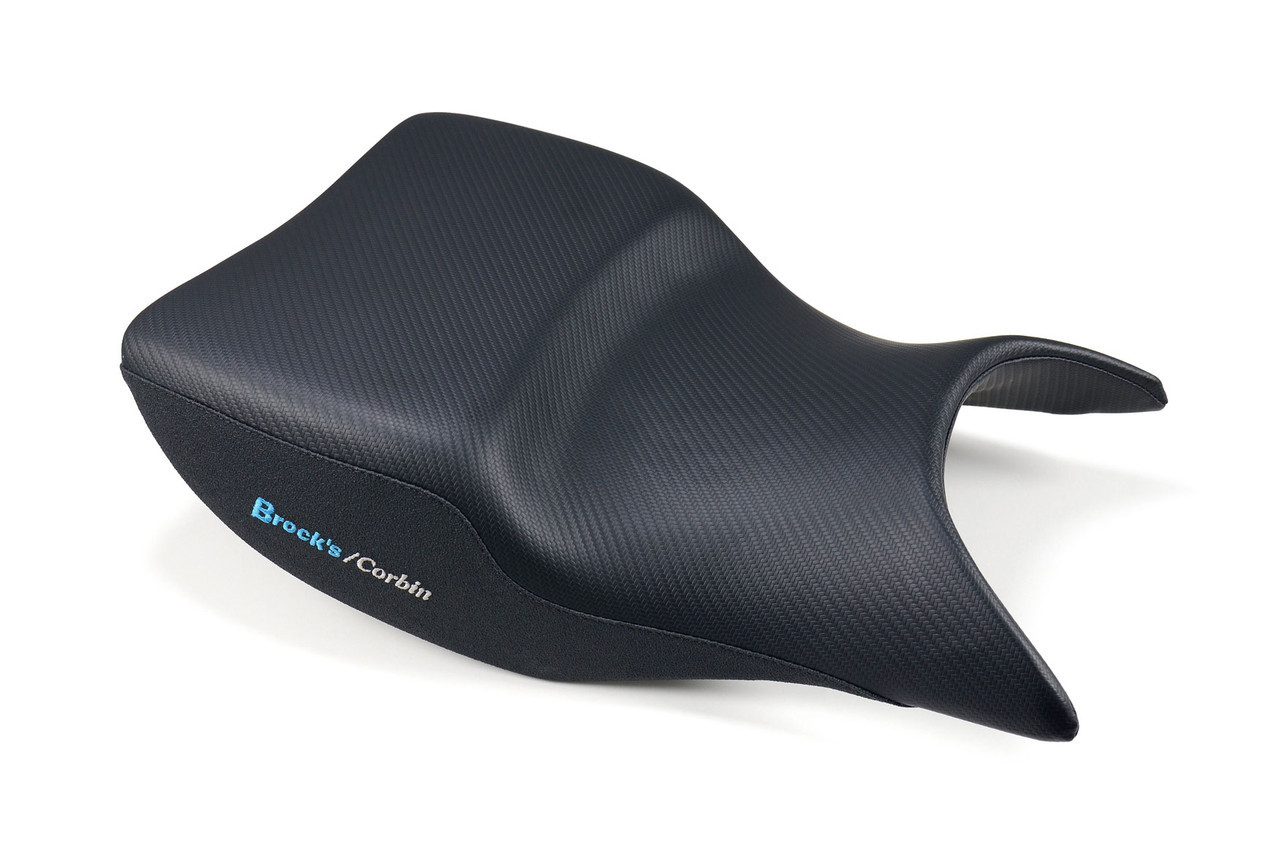

Brock’s Performance pilot saddle greatly enhances the comfort of the bike by ergonomically dispersing your weight over a greater area. Built with Corbin's Comfort Cell® foam to provide countless miles of supportive comfort, the exclusive foam material feels firm at first, but doesn't break down like the stock foam. This keeps your body supported indefinitely for day long riding enjoyment.

Engineered to fit perfect to the tank, chassis and tail section. The saddle is manufactured with a Fibertech™ basepan for unsurpassed fit that rides on rubber bumpers to protect the motorcycle's paint job. To make installation easier, the saddle comes ready to install with pre mounted brackets.

Care Notes: Vinyl is an extremely durable and weather-resistant product and therefore requires little care. It is suggested to avoid any cleaners and/or conditioners that are petroleum-based as they could lead to fading and eventual breakdown of the material. Cleaning can be achieved with Corbin’s Saddle Cream or a similar product.

Note: The Comfort Cell® foam has a memory feature. It will take approximately 1500-2000 miles for the saddle to shape to the rider.

Features:

- Direct replacement for the OEM pilot saddle

- Exclusively made for Brock’s Performance by Corbin

- Custom stepped saddle lowers seat height 1" (25.4mm) vs. OEM

- Comfort Cell® foam provides ultimate comfort and support

- Fibertech™ basepan for unsurpassed fit

- Side panel material: Asphalt Vinyl

(An interesting rough texture that gives good traction and visually a nice contrast) - Seat area material: Carbon Fiber Vinyl Black

(An embossed vinyl material that looks like carbon fiber) - Rides on rubber bumpers to protect the motorcycle's paint job

- Embroidered Brock’s Performance and Corbin logos (both sides)

- Saddle comes ready to install with pre mounted brackets

- Corbin seat weight: 4.20 lb. (1.90 kg) vs. OEM seat weight: 2.40 lb. (1.09 kg)

- Lifetime warranty on basepan, hardware, and foam

Note: This seat was not designed as a lightweight racing seat. The use of premium, layered materials to provide comfort and longevity increases the seat weight when compared to OEM. To offset this increase, the seat has been ‘cut’ in a way that moves your center of gravity forward. This helps to prevent wheelies and provide a better tucked position; while also helping lower seat height and reduce rider fatigue for vertically challenged riders.

- PATENTED MANUFACTURING TECHNOLOGY: The design and manufacture of Corbin products is so unique that Mike Corbin himself holds more than 60 United States Patents! From the manufacturing process itself to the latest engineered materials, you can count on highly functional and unique products that work. Always an innovator, Mike Corbin invented Integrated Molding technology, which is now the process by which all Corbin saddles are made. This process allows extremely tight tolerances and creates a chemical bond between the foam and base material.

- FIBERTECH™ BASEPAN: A purpose built, hybrid material that provides a firm foundation to support the carefully designed ergonomics of the Corbin saddle. It provides a precision fit to every arc and contour of the machine and rides on rubber bumpers to protect your paint.

- COMFORT CELL® FOAM: The heart of the Brock’s Performance saddle by Corbin is the exclusive, purpose-built foam material, called Comfort Cell. The foam was created to provide a firm, resilient ride that doesn't break down during those long days on the road. Continued use of the saddle will allow the foam to contour to your body for ultimate comfort and support.

- ERGONOMIC SHAPING: A major part of the design criteria of the Brock’s Performance saddle by Corbin is the ergonomic shape. This means the saddle's foam shape is designed to emulate the curves of the human body. This provides more square inches of body contact and helps to eliminate hot spots. This shaping also neutralizes the seating platform to help curb sliding in the saddle, which reduces rider fatigue.